Low-temperature polycrystalline silicon (LTPS) is polycrystalline silicon that has been synthesized at relatively low temperatures (~650 °C and lower) compared to in traditional methods (above 900 °C). LTPS is important for display industries, since the use of large glass panels prohibits exposure to deformative high temperatures. More specifically, the use of polycrystalline silicon in thin-film transistors (LTPS-TFT) has high potential for large-scale production of electronic devices like flat panel LCD displays or image sensors.

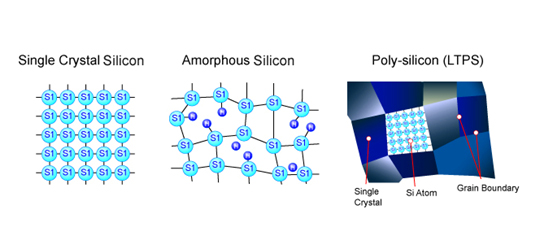

Polycrystalline silicon (p-Si) is a pure and conductive form of the element composed of many crystallites, or grains of highly ordered crystal lattice. In 1984, studies showed that amorphous silicon (a-Si) is an excellent precursor for forming p-Si films with stable structures and low surface roughness. Silicon film is synthesized by low-pressure chemical vapor deposition (LPCVD) to minimize surface roughness. First, amorphous silicon is deposited at 560–640 °C. Then it is thermally annealed (recrystallized) at 950–1000 °C. Starting with the amorphous film, rather than directly depositing crystals, produces a product with a superior structure and a desired smoothness. In 1988, researchers discovered that further lowering temperature during annealing, together with advanced plasma-enhanced chemical vapor deposition (PECVD),could facilitate even higher degrees of conductivity. These techniques have profoundly impacted the microelectronics, photovoltaic, and display enhancement industries.

In 1984, studies showed that amorphous silicon (a-Si) is an excellent precursor for forming p-Si films with stable structures and low surface roughness. Silicon film is synthesized by low-pressure chemical vapor deposition (LPCVD) to minimize surface roughness. First, amorphous silicon is deposited at 560–640 °C. Then it is thermally annealed (recrystallized) at 950–1000 °C. Starting with the amorphous film, rather than directly depositing crystals, produces a product with a superior structure and a desired smoothness. In 1988, researchers discovered that further lowering temperature during annealing, together with advanced plasma-enhanced chemical vapor deposition (PECVD),could facilitate even higher degrees of conductivity. These techniques have profoundly impacted the microelectronics, photovoltaic, and display enhancement industries.

LTPS is needed for:

1. Circuits on glass – integrated drivers and scanners and multiplexer – reduces use of external IC and connectors to panel

2. Much smaller TFT ⇒ larger aperture ratio – mobile applications

3.Much more stable than a-Si under high current loading (OLED needs current to drive)